Iprotech vitreous enameling factory is located in Foshan city, China. Foshan City is the well-known area offering highest grade vitreous enamel service in China. Benefited from the regional advantage and cooperated with our contracted subcontractors, we are able to deliver high quality enameling coated prototype in variety of colors, and the part size can go up to 39.0 inches * 43.0 inches(length* width).

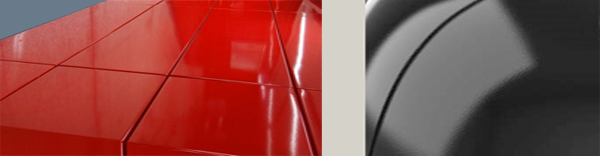

Vitreous enamel, also called porcelain enamel, is a material made by fusing powdered glass to a substrate by firing, usually between 750 and 850 °C (1,380 and 1,560 °F). The powder melts, flows, and then hardens to a smooth, durable vitreous coating on metal, or on glass or ceramics. Vitreous enamel can be applied to most metals.

For prototype parts required to apply vitreous enamel coating(including deep drawn sheet metal prototype), the raw material must be specific low-carbon steel. This type of specific low-carbon steel has already been applied with some specific treatments based on common low-carbon steel, with these specific treatments or improvements, it can finally get high quality enameling coated parts without bubbles, needle hole and especially the scale chipping issues. Thus, the correct raw steel material selection is one of the key factors to get high quality enameling coated parts. On other hand, during the part fabricating phase, the fabricating processes and methods also need to be well planned and managed to get final high quality enameling coated parts. For example, the welded area is quite sensitive to enameling quality, usually those welded areas are easily found with enameling chipping issue, so it needs to avoid welding or strictly controlling welding area and welding technology.

Start your project today! The team at Iprotech is always fulfilled with passion and professionalism to assist you to turn your innovative ideas into practical solution.