Quick quality prototype stamping service at competitive price is the promise from Iprotech team. Especially for deep drawn prototype stamping parts, this is the core competitiveness at Iprotech comparing with most of the other competitors, and we are striving to be your #1 supplying choice when you have deep drawn prototype stamping demands.

Capacities of prototype stamping:

A stamping prototype part with medium complexity design usually involves the forming operations such as deep draw stamping, trimming, bending and or roll forming etc. Iprotech provides one-step service to supply prototype stamping parts with all these processes done in good quality and high efficiency. Our prototype stamping capabilities are as below,

(1) material range including SAPH series for vehicles, hot or cold-rolled mild steel, stainless steel, copper and aluminum etc.

(2) sizes range goes up to 70 inches x 30 inches, and up to 20 inches in depth.

(3) 1 to 500 deep drawn prototype stamping parts or small amount sheet metal deep draw stamping production from 3 to 25 days.

Processes of prototype stamping:

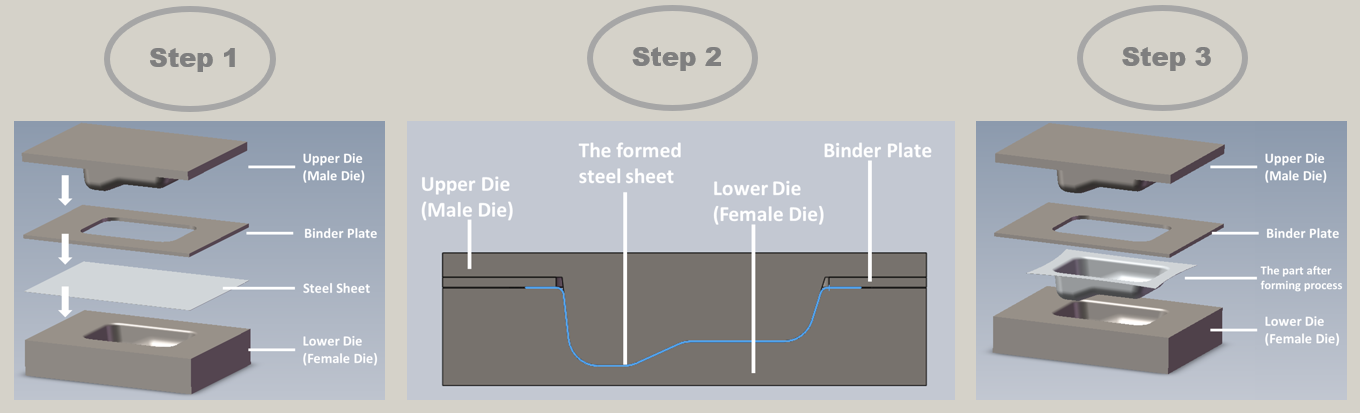

Among all these processes of a prototype stamping, the deep draw stamping process is one of the key factor to quality, cost and lead-time, this is because deep draw process usually needs specific deep draw tools for forming, while tight timeframe of prototype is the normal state. Thus, rapid prototyping technology is quite important for delivering good quality parts on-time. The following steps and illustration show how Iprotech to make a hollowed sheet metal prototype part by deep draw stamping way.

Step 1: prepare the deep draw forming dies and the flat raw sheet metals.

Step 2: forming operation done by hydraulic press machine.

Step 3: get primary correct shaped part per design.

Step 4, 5… the others like trimming, bending or other stamping or rolling process etc.

Machinery of prototype stamping:

To make big and deep drawn prototype stamping parts, it requires the factory has rich experienced designer for deep drawing tools rsquo; design, large CNC and hydraulic deep drawing machinery.At Iprotech, with experiences rsquo; accumulation for more than 19 years in deep drawn prototype stamping and equips with sufficient machinery, these advantages ensure us to deliver good quality parts on time in competitive price.

Raw material of prototype stamping:

The raw material is another key factor to prototype stamping, Iprotech cooperates with large scale raw material supplier, so we can almost 100% meet your expectations of raw material specifications including many types of specific steel grades in variety for vehicles. But for some specific cases, for example you may need a high-quality enameling coated prototype part, then we must use specific steel sheet raw material, because only correct or specific raw material can ensure successfully presenting the final high-quality enameling coated part. For more than 19 years, Iprotech is being the expert on raw material purchasing and usage management for prototype stamping.

Service of prototype stamping:

We understand the intricacies of prototype stamping, starting from our the first time contact, our sales team works with engineering, quality control and the whole manufacturing team cares every detail of your project, included but not limited to the phase of engineering evaluation, prototype tools design, first article inspection-FAI and final inspection before shipment. To achieve the goal of delivering good quality prototype on time and on your budget,we always do the best to assist you to procure the most economical solution under no quality reduction condition, closely monitoring the whole manufacturing process and carry out strict quality controlling procedures.

Get it right, first time, every time! Iprotech promises!

Start your project today! The team at Iprotech is always fulfilled with passion and professionalism to assist you to turn your innovative ideas into practical solution.